Between 2015 and 2021, the global autoclaved aerated concrete market is expected to increase by just under $2 billion USD. AAC is increasing in industry wide use due to its light weight and versatility. The construction material consists of fly ash and gypsum, both biproducts of burning coal to make energy, and much less costly than their alternatives, sand and anhydrite. The material also consists of lime, cement, and aluminum powder. Construction companies are increasing their use of this material as it is not only more cost efficient, but also provides wider durability to seismic fluctuation, intense heat, and pests. The material itself also saves the manufacturer or construction company in water and energy usage. Autoclaved aerated concrete is widely used in Europe and North America.

AAC materials can either be used instead of or to repair common building materials. Application can be seen in most real estate areas including residential, industrial and commercial. However, the majority of the AAC market has been residential since its inception, and continuing throughout 2017 with a third of the overall market. The product types of autoclaved aerated concrete are distributed into tiles, panels, blocks, lintels and others.

The growing market is propelled by elements such as the increased importance of utilizing green building materials, the use of recycled materials themselves (fly ash, etc), and its superiority to commonly used materials for the same purpose.

Currently, limited adoption is due to high start up costs associated with AAC, and because manufacturing facilities are not yet commonplace, resourcing and logistics becomes problematic.

As adaptation grows however, and infrastructure is set in place, the forecast for AAC paneling is projected to grow almost 8% in the next 5 years.

Globally, Europe has lead in market consumption. However, the Asia Pacific region, including countries like China, Thailand, Malaysia, Singapore and Indonesia are expected to increase consumption by over 10%, also within the next 5 years.

Opportunities in the AAC market are real as there is strong interest in China, India and other densely populated regions who would benefit from disaster resistant structures made from coal combustion products (CCPs).

To read more about autoclaved aerated concrete construction, trends, and forecasts for investment and integration, please read Orbis Research’s report: Global Autoclaved Aerated Concrete (AAC) Market-Segmented by Type, Application (Construction), and Geography-Trends and Forecasts (2017-2022). Follow the link in the text for more information.

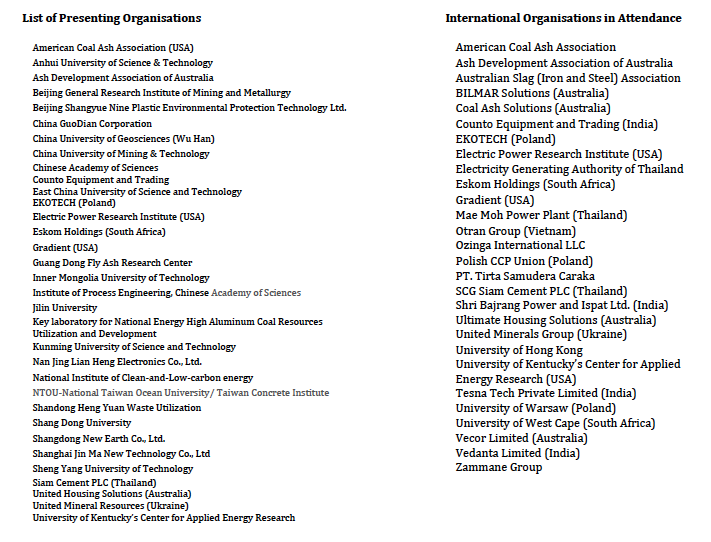

To learn more about global trends and research on AAC and CCPs, join us at Coal Ash Asia 2018.