Research Highlight: Northeastern University School of Metallurgy

/Shenyang City, China

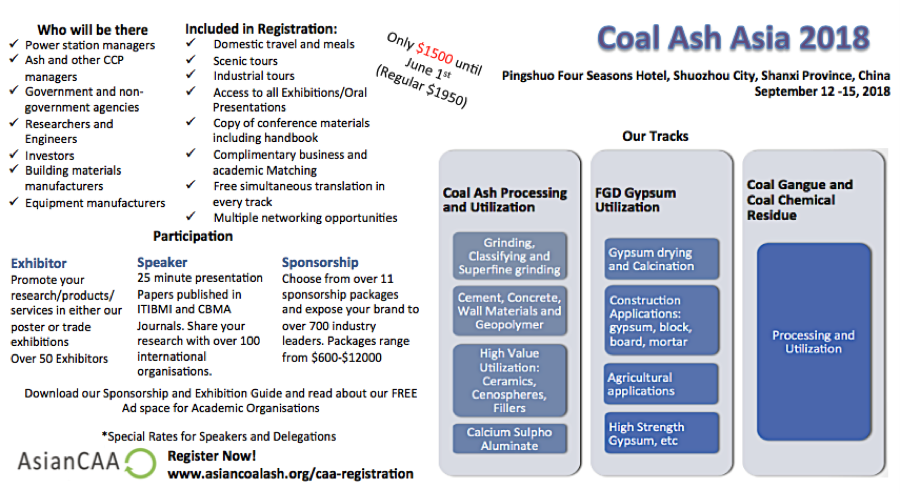

Northeastern University is a public university in Shenyang, Liaoning Province with strengths in engineering and architecture. It is known for its prominent role in the information technology industry. Professor Shi Peiyang and the team from Northwestern University’s School of Metallurgy joined over 700 industry leaders at last year’s Coal Ash Asia conference and exhibition. Asian Coal Ash Association and the Institute for Technical Information for the Building Materials Industry hosted the annual event in Shuozhou City, China, last September. Below is an abstract from Prof. Shi Peiyang focusing on reducing air pollution from coal-fired power stations. Click below the abstract to discover more of his research.

The Key Technologies for Cleaning and Recycling Utilization of Desulfurized Flue Gas By-products

Abstract: Desulfurization ash is one of the by-products of dry lime flue gas desulphurization of sintering process in steel company. The utilization of the desulfurization ash is a challenge since it contains calcium sulfite, chloride-bearing phases and carbon. With rapid development of steel industry and more stringent requirement of environment supervision, reasonable treatment of desulphurized ash has become a key problem for the sustainable development of dry lime flue gas desulfurization. Therefore, realizing the comprehensive utilization of desulphurization ash plays an important role in promoting the dry flue gas desulphurization technology, and has important practical significance for the governance of haze problem. In this work, the desulfurization ash was used as a raw material for the preparation of calcium sulfate whisker via hydrothermal method. The effects of process parameters on the growth behavior of calcium sulfate whiskers were experimentally investigated, and the dissolution behavior of calcium sulfate in aqueous solution was studied. The molecular dynamics method was applied to simulate the growth habit of calcium sulfate crystal. Based on this, the modification mechanism of calcium sulfate whisker was deeply analyzed. Furthermore, the effects of the calcium sulfate whiskers before and after modification on the performance of rubber, asphalt and ceramic for centrifugal pump was characterized.